Due to recurring customer inquiries, Griffner Metallveredelung decided to set up a blasting system. After carefully checking requirements, a Tunnelblast blasting system tailored to our requirements was planned in close cooperation with the plant manufacturer and extensive construction work began in March 2020. Completion date continue reading > has been postponed to July 2020 due to ‘Corona’.

With a max. workpiece width of 1000mm and a max. workpiece height of 2000mm, we will be able to blast workpieces up to a weight of 1500kg in our system.

Furthermore, with our system it will be possible to sweep galvanised material. This process is used to prepare galvanised material in the best possible way for optimal adhesion of the powder coating and to enable a high quality coating.

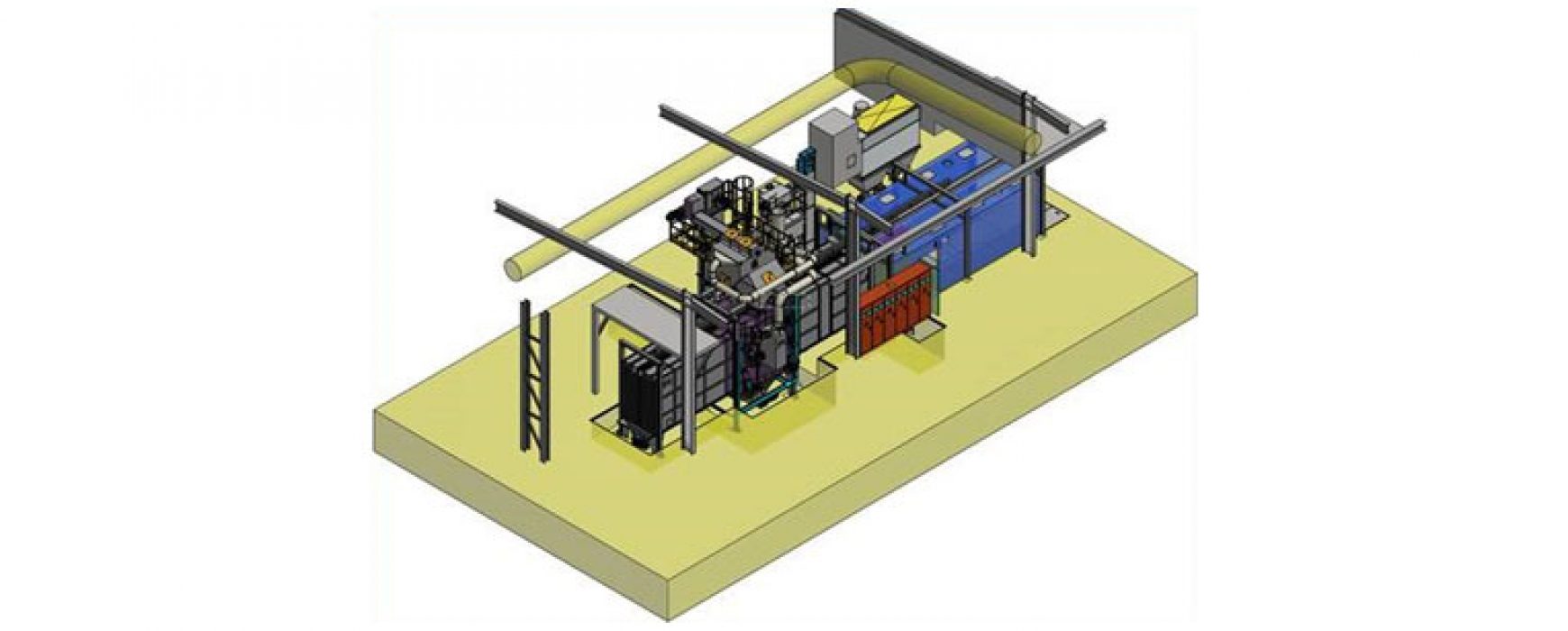

In the first construction phase, the existing hall is adapted and the foundation stone is laid for the construction of the plant. The blasting system is built in direct connection to the existing production facilities in order to guarantee the shortest possible routes.

Environmental aspects are also fulfilled with this system. Not only are additional transport routes avoided, but blasting material is also cleaned in an abrasive reprocessing system integrated into the system and can then be returned to the blasting process.

For you as a customer, this has the advantage that additional transport routes are avoided and the total lead times of the workpieces can be shortened. From blasting to the final coating, all work can now be carried out in-house.